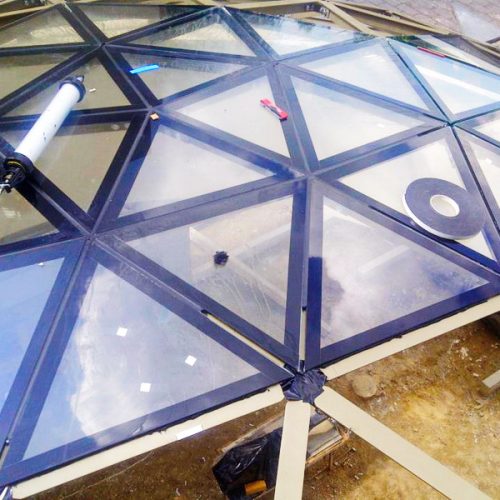

If partaking in this project as a group again, the main alteration we would make to our process would most definitely be the connections of the structural triangles. As can be seen in the image below it started to fall apart towards the end of our construction because the aluminium rings we used to connect the timber were significantly flimsy. There was multiple reasons why we had to chose aluminium as connections such as budget and equipment constrain. The aluminium sheeting was thin enough to be able to be cut with scissors.

Further more this alteration would have benefited the construction of the window. It was difficult to get the window frame to sit right due to the organic shape created by the instability of the connections used. Contrary to these predicaments, we were still able to get the window in place and waterproofed with no leaks throughout the water test.

A further error was made when cladding one of the panels because the size of one cardboard

panel was incorrectly calculated. This results in a small gap between the panel and the timber frame, which can also be seen in the image below.

Due to material constrain, we were unable make another waterproof cardboard panel. Terefore we used the off-cuts of the material to cover the gaps.

For ease of demolition we used timber screws. We will unscrew the structure and reuse the timbers and cardboard for future projects.

Overall, the geodesic dome was structurally not sound but it was successful in keeping water out and was able to stand on its own which we were proud of.